Falcon 9 Videos

|

Loading...

|

|

Falcon 9

Falcon 9 launches with first Dragon spacecraft

Manufacturer: SpaceX

Country of origin: United States

Cost per launch (2011): Normal:

LEO (80% cap.) $49.9M

LEO (;80% cap.) $56.0M

GTO (3,000 kg) $49.9M

GTO (;3,000 kg) $56.0M

Heavy: $95m

Size:

Height: 54.3 m (178 ft)

Diameter: 3.66 m (12.0 ft)

Mass: Normal: 333,400 kg (735,000 lb)

Heavy: 885,000 kg (1,950,000 lb)

Stages: 2

Capacity:

Payload to LEO: Normal: 10,450 kg (23,000 lb)

Heavy:32,000 kg (71,000 lb)

Payload to

GTO: Normal: 4,540 kg (10,000 lb)

Heavy: 19,500 kg (43,000 lb)

Launch history:

Status: Active

Launch sites: Cape Canaveral SLC-40

Vandenberg SLC-4E

Omelek Island

Total launches: 2

Successes: 2

Failures: 0

Maiden flight: Normal: June 4, 2010

Heavy: none scheduled

Boosters (Falcon 9 Heavy (proposed)):

â boosters: 2

Engines: 9 Merlin 1C

Thrust: 5,000 kN (1,100,000 lbf)(sl)

Specific impulse: Sea level: 255 sec (2.6 kN/kg)

Vacuum: 304 sec (3.0 kN/kg)

Burn time: Unknown

Fuel: LOX/RP-1

First stage:

Engines: 9 Merlin 1C

Thrust: 5,000 kN (1,100,000 lbf)(sl)

Specific impulse: Sea level: 255 sec (2.6 kN/kg)

Vacuum: 304 sec (3.0 kN/kg)

Burn time: 170 seconds

Fuel: LOX/RP-1

Second stage:

Engines: 1 Merlin Vacuum

Thrust: 445 kN (100,000 lbf)

Specific impulse: Vacuum: 342 sec (3.45 kN/kg)

Burn time: 345 seconds

Fuel: LOX/RP-1

LEO (80% cap.) $49.9M LEO (;80% cap.) $56.0M GTO (3,000 kg) $49.9M GTO (;3,000 kg) $56.0M Heavy: $95m

Falcon 9 is a spaceflight launch system that uses rocket engines designed and manufactured by SpaceX. Both stages of the two-stage-to-orbit vehicles use liquid oxygen (LOX) and rocket-grade kerosene (RP-1) propellants. Multiple variants are planned with payloads of 10,450-26,610 kilograms (23,000-58,700 lb) to low Earth orbit, and 4,450-15,010 kilograms (9,800-33,100 lb) to geostationary transfer orbit, which will place the Falcon 9 design in the medium-lift to heavy-lift range of launch systems.

The first Falcon 9 flight was successfully launched from Cape Canaveral Air Force Station on June 4, 2010 14:45 EDT (19:45 UTC) with a successful orbital insertion, after several delays.

The Falcon 9 is the launch vehicle for the SpaceX Dragon spacecraft. The Falcon 9 and Dragon combination won a Commercial Resupply Services (CRS) contract from NASA to resupply the International Space Station under the Commercial Orbital Transportation Services (COTS) program. The second Falcon 9 launch, and the first launch of the Dragon spacecraft, occurred at 10:43 EST (15:43 UTC) on December 8, 2010 from Cape Canaveral. The launch was successful, with the Dragon spacecraft completing two orbits before splashing down in the Pacific Ocean.

Design

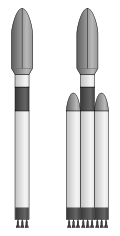

Picture - Falcon 9 (left) and Falcon 9 Heavy (right)

The base Falcon 9 is a two stage, LOX/RP-1 powered launch vehicle. Its first stage is powered by nine SpaceX Merlin 1C rocket engines with 556 kN (125,000 lbf) sea-level thrust per engine for a total thrust on liftoff of approximately 5.0 MN (1.1 million lbf). The Falcon 9 first stage uses a pyrophoric mixture of triethylaluminum-triethylborane (TEA-TEB) as a first-stage ignitor.

The proposed Falcon 9 Heavy configuration consists of a standard Falcon 9 with two additional Falcon 9 first stages acting as liquid strap-on boosters, which is conceptually similar to EELV launchers Delta IV Heavy and the future Atlas V HLV, and also to the Russian Angara carrier rocket.

The upper stage is powered by a single Merlin engine modified for vacuum operation, with an expansion ratio of 117:1 and a nominal burn time of 345 seconds. For added reliability of restart, the engine has dual redundant pyrophoric igniters (TEA-TEB). SpaceX has expressed hopes that both stages will eventually be reusable.

The interstage, which connects the upper and lower stage for Falcon 9, is a carbon fiber aluminum core composite structure. Stage separation occurs via reusable separation collets and a pneumatic pusher system. The Falcon 9 tank walls and domes are made from aluminum lithium alloy. SpaceX uses an all friction stir welded tank, the highest strength and most reliable welding technique available. The second stage tank of Falcon 9 is simply a shorter version of the first stage tank and uses most of the same tooling, material and manufacturing techniques. This results in significant cost savings in vehicle production.

Reliability

As with the company's smaller Falcon 1 vehicle, Falcon 9's launch sequence includes a hold-down feature that allows full engine ignition and systems check before liftoff. After first stage engine start, the launcher is held down and not released for flight until all propulsion and vehicle systems are confirmed to be operating normally. Similar hold-down systems have been used on other launch vehicles such as the Saturn V and Space Shuttle. An automatic safe shut-down and unloading of propellant occurs if any abnormal conditions are detected.

Like the Saturn V and the unrealized Falcon 5 design, the presence of multiple first stage engines allows for mission completion even if an engine fails mid-flight. This is known as "engine-out capability". Falcon 9 is the first rocket "since the Saturn series from the Apollo program to incorporate engine-out capability"

Falcon 9 will have triple redundant flight computers and inertial navigation, with a GPS overlay for additional orbit insertion accuracy.

Reusability

Although the first stage has parachutes and was intended to be recovered to demonstrate (possible future) reuse, to date SpaceX has failed to recover the stages from their initial test launches. The stages are expendable for the initial launches. By flight six, the first stage is intended to be recovered. Although reusability of the second stage is more difficult, SpaceX has intended both stages of the Falcon 9 to be reusable. Musk stated:

"By flight six we think itâs highly likely weâll recover the first stage, and when we get it back weâll see what survived through re-entry, and what got fried, and carry on with the process. ... That's just to make the first stage reusable, it'll be even harder with the second stage - which has got to have a full heatshield, it'll have to have deorbit propulsion and communication."

Both stages are covered with a layer of ablative cork, have parachutes to land them gently in the sea and have been marinised by using salt water resistant materials, anodizing and paying attention to the issue of galvanic corrosion.

While many commentators are skeptical of the viability of reusability, Musk has stated that reusability is one of the most important goals, and that if the vehicle does not become reusable, "I will consider us to have failed.â

Launch sites

There is one active launch site and two others are planned/proposed:

Cape Canaveral Air Force Station Launch Complex 40 is an active Falcon 9 launch site.

SpaceX plans to lease Vandenberg AFB Space Launch Complex 4. Conversion of the site for Falcon 9 is estimated to cost $50 million and the first launch is due in summer 2012. As of June 2010, CEO Elon Musk indicated he is confident that a Vandenberg launch pad can be ready for Iridium satellite launches "within 12 to 18 months".

SpaceX may upgrade their Omelek Island Falcon 1 launch site for use by the Falcon 9; as of December 2010, their launch manifest gives Omelek (Kwajalein) as a possible site for several Falcon 9 launches, the first as an alternative for the Argentina CONAE mission in 2012.

Launcher versions

Historical data based on circa 2007 specifications may be found in these three sources.

Initial descriptions

At an appearance in May 2004 before the U.S. Senate Committee on Commerce, Science and Transportation, Elon Musk testified, "Long term plans call for development of a heavy lift product and even a super-heavy, if there is customer demand. [...] Ultimately, I believe $500 per pound [of payload delivered to orbit] or less is very achievable."

SpaceX formally announced the Falcon 9 on 2005-09-08, describing it as being a "fully reusable heavy lift launch vehicle." A Falcon 9 medium was described as being capable of launching approximately 21,000 lb (9,500 kg) to low Earth orbit, priced at $27 million per flight ($1286/lb).

Production and testing

As of December 2010, the Falcon 9 production line is manufacturing one new Falcon 9 (and Dragon spacecraft) every three months. In 2012, this will double to one every six weeks.

Production history

On April 12, 2007 SpaceX announced it had completed the primary structure for its first Falcon 9 first-stage tank. The tank was shipped to a SpaceX test facility in Texas for first-stage static firing validation. The first multi-engine test (with two engines connected to the first stage, firing simultaneously) was successfully completed in January 2008, with successive tests leading to the full Falcon 9 complement of nine engines test fired for a full mission length (178 seconds) of the first stage on November 22, 2008.

The original NASA COTS contract called for the first demonstration flight of Falcon in September 2008, and completion of all three demonstration missions by September 2009. February 2008, the plan for the first Falcon 9/Dragon COTS Demo flight was delayed by six months to late in the first quarter of 2009. According to Elon Musk, the complexity of the development work and the regulatory requirements for launching from Cape Canaveral have contributed to the delay. The first COTS demo flight was delayed several additional times, and was eventually scheduled for December 2010.

In October 2009, the first flight-ready first stage had a successful all-engine test fire at the company's test stand in McGregor, TX. In November 2009 Space X conducted the initial second stage test firing lasting forty seconds. This test involved a new test stand and a new flight stage, and succeeded without aborts or recycles. On January 2, 2010, a full-duration (329 seconds) orbit-insertion firing of the Falcon 9 second stage was conducted at the McGregor test site The full stack arrived at the launch site for integration at the beginning of February 2010, and SpaceX initially scheduled a launch date of March 22, 2010, though they estimated anywhere between one and three months for integration and testing.

On February 25, 2010 SpaceX's first flight stack was set vertical at Space Launch Complex 40, Cape Canaveral, and on March 9, SpaceX performed a static fire test, where the first stage was to be fired without taking off. Some fire and smoke were seen at the base of the rocket, leading to speculation of an engine fire. However, all components checked out, but the test executed a nominal abort at T-2 seconds due to a failure in the spin-start system. This system is designed to pump high pressure helium from the launch pad into the first stage turbopumps to get them spinning in preparation for launch. Subsequent review showed that the failure was a valve that didn't receive a command to open. As the problem was with the pad and not with the rocket itself, it didn't occur at the McGregor test site, which didn't have the same valve setup. No damage was sustained by the vehicle or the test pad and the fire and smoke were the result of normal burnoff from the liquid oxygen and fuel mix present in the system prior to launch. All vehicle systems leading up to the abort performed as expected and no additional issues were noted that needed addressing. A subsequent test on March 13 was successful in firing the nine first-stage engines for 3.5 seconds.

The delay of the first flight from March 2010 to June was due to review of the Falcon 9 flight termination system by the Air Force. On June 1, SpaceX announced on their update page that they had completed testing of the FTS and all results were nominal.

The first actual launch attempt, at 1:30pm EDT on Friday, June 4, 2010 (1730 UTC), was aborted shortly after ignition, and the rocket successfully went through a failsafe abort. Ground crews were able to recycle the rocket, and successfully launched it at 2:45pm EDT (1845 UTC) the same day.

Maiden Launch

Picture - Launch video (1 min 52 secs)

The Falcon 9 maiden launch occurred on June 4, 2010 and was deemed a success, placing the test payload within 1 percent of the intended orbit. The second stage engine performed a short second burn to demonstrate its multiple firing capability.

The rocket experienced, "a little bit of roll at liftoff" as Ken Bowersox from SpaceX put it. This roll had stopped prior to the craft reaching the top of the tower. The second stage began to slowly roll near the end of its burn which was not expected, and the first stage parachutes failed to open causing it to be damaged upon landing.

The halo from the venting of propellant from the Falcon 9 rocket as it rolled in space could be seen from all of Eastern Australia and some believed it to be a UFO.

Continued development

Picture - SpaceX Falcon 9 launch with COTS Demo Flight 1

The next launch attempt for Falcon 9 was COTS Demo Flight 1, with an operational Dragon module. The launch took place on December 8, 2010. The flight placed the Dragon capsule in a roughly 300-kilometer (190 mi) orbit. After two orbits, the capsule re-entered the atmosphere to be recovered off the coast of Mexico. This flight tested the pressure vessel integrity, attitude control using the Draco engines, telemetry, guidance, navigation, control systems, the PICA-X heat shield, and parachutes at speed.

Launches and scheduled launches

Comparison of medium lift launch systems

Comparison of mid-heavy lift launch systems

Comparison of heavy lift launch systems

Falcon 9 Pictures

Living Warbirds: The best warbirds DVD series.

Source: WikiPedia